Fastfoot® revolutionizes concrete footing forming with its high-density polyethylene fabric, replacing traditional lumber and plywood.

Each 100′ roll of Fastfoot® equals the concrete-forming capacity of 1,500 pounds of lumber, offering unmatched efficiency.

Now available in three colors, Fastfoot® features printed width lines and QR codes for easy onsite installation referencing.

Recognized as the Contractors’ Choice product of the year in 2010 and 2012, Fastfoot® is trusted for residential and commercial strip footings and pad edging.

ADVANTAGES

Less Expensive than lumber

Fastfoot is significantly less expensive than dimensional lumber to form concrete footings.

Adapts to Uneven Ground, Rock

Special colored width lines allow Fastfoot® to be ‘let out’ or ‘pulled in’ to accommodate uneven excavations.

No need to scab lumber on the sides of your footings or shovel the ground to achieve the footing depth.

Fastfoot® is perfect over rock as shown in this photo.

Ideal for Stepped Footings

Fastfoot® quickly adapts to the uneven contours of your bank. No need to waste plywood.

Forms Deep Footings

Fastfoot® is ideal for deep footings and commercial pads. Form footings up to 4′ deep.

Eliminate expensive and heavy plywood and eliminate expensive re-cycling of formwork.

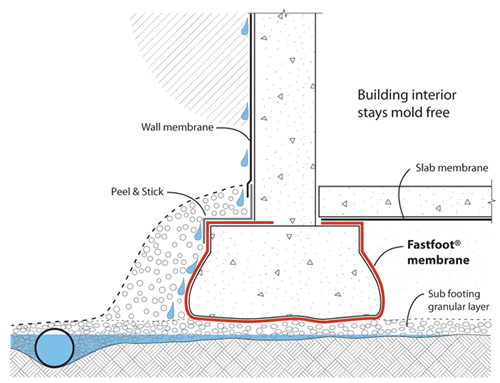

Prevents Rising Damp

Concrete is ‘hygroscopic’, wicking up ground moisture which leads to a damp and moldy interior.

Fastfoot® is a damp proof membrane, preventing ground moisture wicking into the footing concrete, providing a drier, healthier indoor environment.

Prevents Ground Water Contamination

Fastfoot® is a closed form, preventing cement fines from entering the water table.

Stronger Concrete

As the picture above shows, Fastfoot® prevents the footing concrete from being contaminated by mud and water, leading to a stronger concrete.

In the summer, Fastfoot® prevents rapid evaporation of moisture in the sides and bottom of the footing. This ensures adequate moisture for proper hydration of the cement particles.

Greener

Fastfoot® is LEED® contributing and GreenSpec® listed.

Conserves Natural Resources

A single 12.5 pound roll of Fastfoot® forms the same footing as 900 pounds of lumber, representing a dramatic increase in efficiency. Footing lumber is discarded after several reuses because of alkaline damage. Fastfoot® protects all lumber and stakes from concrete.

The photo on the right shows the typical footing lumber on a residential foundation in Vancouver BC. The photo insert shows Fastfoot® with sewn corners, where not a single piece of lumber was used to form the concrete. The fabric stays in place to prevent ground moisture from entering the foundation concrete.

There are seven categories where Fastfoot® contributes:

| Main section | Subsection | Detail | Explanation |

|---|---|---|---|

| 1 – Sustainable Sites | Prereq 1 | Construction Activity Pollution Prevention | With lumber footing forms, concrete is poured directly on the ground, contaminating the water table with cement toxins. With Fastfoot® the concrete is poured into a membrane, preventing all ground water contamination. |

| 2 – Materials & Resources | Prereq 1 | Storage & Collection of Recyclables | Lumber formed concrete footings are not environmental because of transportation, storage, and waste. Approximately 35% of lumber forms are sent to the landfill. Fabric forms are very green: 300 times lighter and 1% the space of lumber, and stay in place to prevent ground moisture entering the concrete and causing mold and health issues. |

| 3 – Materials & Resources | Credit 2.1 | Construction Waste Management: Divert 50% from Disposal | Fabric forms divert 100% of forming materials from disposal. Any lumber used is completely protected by Fastfoot® from concrete damage and is reused. |

| 4 – Materials & Resources | Credit 8 (Canada) | Durable Building | Fastfoot® prevents rapid hydration leading to stronger and more durable concrete. Lumber forms lead to excessive drying and weaker concrete. |

| 5 – Materials & Resources | Credit 8 (Canada) | Durable Building | Fastfoot® eliminates rising damp, thereby preventing the deterioration of the building structure and interior finishes from mold and dampness. |

| 6 – Indoor Environmental Quality | Credit 3.1 | Construction IAQ Management Plan: during Construction | Fabric forms for footings stay in place to act as a permanent membrane, preventing rising damp through the concrete and into the building interior. Elevated moisture levels are linked to mold and the proliferation of other indoor air borne pathogens that directly affect human health. |

| 7 – Innovation & Design Process | Credit 1.1 | Innovative Performance not specifically addressed by LEED® | Fabric formwork for concrete footings is a dramatic innovation over temporary lumber forms. This technology is not only more efficient than lumber forms, but offers ongoing benefits to the building occupants for the life of the structure. |